Herstellung von Blechen für Schaltschränke

Blechbearbeitung Fertigung

.

Blech hat die Eigenschaften geringes Gewicht, hohe Festigkeit, elektrische Leitfähigkeit (kann zur elektromagnetischen Abschirmung verwendet werden), niedrige Kosten und gute Massenproduktionsleistung. Es ist weit verbreitet in elektronischen Geräten, Kommunikation, Automobilindustrie, medizinischen Geräten und anderen Bereichen, wie z. B. in Computergehäusen, Mobiltelefonen und MP3-Playern, Blech ist ein unverzichtbarer Bestandteil. Mit der zunehmenden Anwendung von Blech ist die Konstruktion von Blechteilen zu einem sehr wichtigen Teil des Produktentwicklungsprozesses geworden. Maschinenbauingenieure müssen die Konstruktionsfähigkeiten von Blechteilen beherrschen, damit das konstruierte Blech den Anforderungen des Produkts entspricht. Die Anforderungen an Funktion und Aussehen können die Herstellung des Stanzwerkzeugs einfach und kostengünstig machen.

|

Materialien vorhanden

|

Aluminum, Copper, St

ainless steel, I

ron, PE, PVC, ABS, etc.

|

|

Surface treatment

|

Polishing, Painting, A

nodizin

g, Brushing, general/hard/color oxidation, tempering, etc.

|

|

Processing type

|

CNC T

urning, Milli

ng, drilling, auto lathe, tapping, bushing, surface treatment, etc.

|

|

Tolerance of CNC Machining

|

Metal:+/-0.05mm or less ; Plastic :+/-0.1mm

|

Testing Equipment

|

CMM/Tool microscope/multi-joint arm/Automatic height gauge/Manual height gauge/Dial gauge/Roughness measurement

|

|

Our Advantages

|

1.) 24 hour online service & rapid quote and delivery.

2.) 100% QC quality inspection before shipping, and can provide quality

inspection form.

3.) 20+ years of experience CNC machining for massive range of industries. On site engineering team can offer modification suggestions.

4.) With more than 200 industrial quality CNC machine we can provide premium service and rapid delivery

|

|

Delivery date

|

Normally 3~7 days,but some of them depend on the quantites

request. Send us your 3d files and your specific requirements, we will get back to you with the quotation including the lead times

|

|

Our Service

|

CNC Machining

Service

Rapid prototyping Service

Injection Molding Service

Vacuum casting Service

Aluminum extrusion Service

Sheet Metal Fabrication Service

|

|

Packaging&Transport

|

Wood case or carton box,

1,With plastic bag, with pearl-cotton package.

2,To be packed in cartons or wood case.

3,Use tape to seal cartons. Or nail shut wooden crates

4,Deliver by DHL,FEDEX, UPS. Or according to customers' requirement.

|

Q1:

How To ensure customers drawings will not be released ?

A: We have the Responsibilities and obligations to keep clients design and drawings as secrets , so if needed we would like sign a NDA ( nondisclosure agreement) with clients and a non-disclosure bond with our staff . Meanwhile clients Shall be investigated for responsibility when this happened.

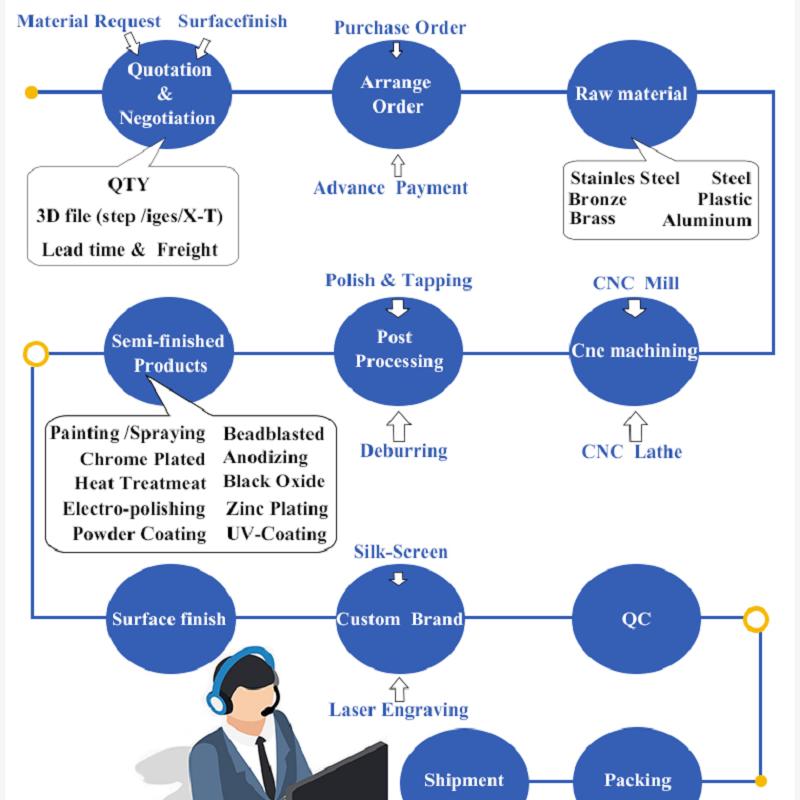

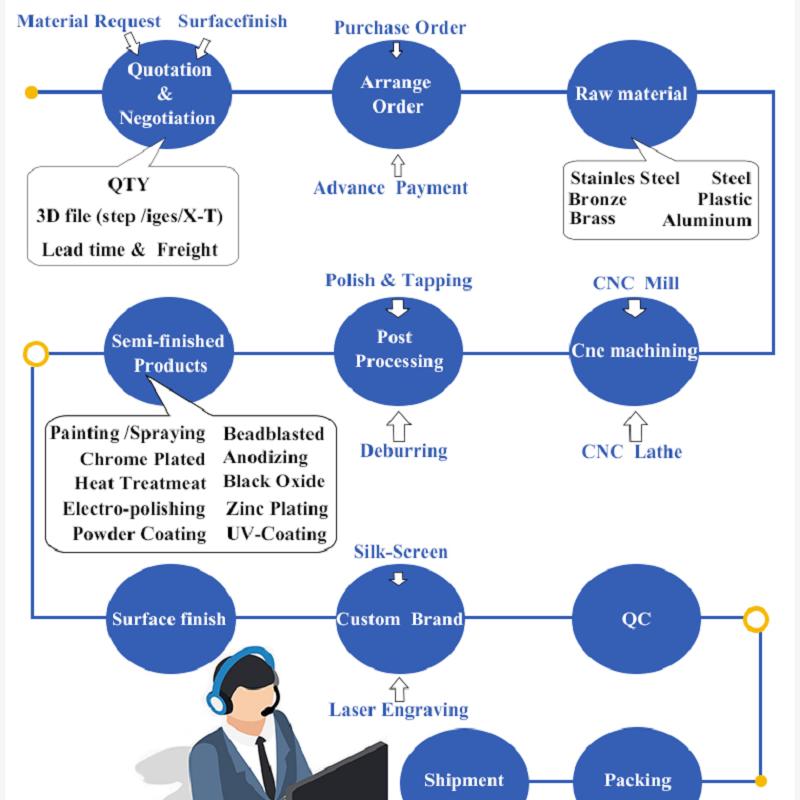

Q2: What will you need from customers to do with offers and production?

A: We called this “ four Key elements ” , they are :Drawings( 2D and 3D of IGES / STEP / PRT / X-T ,Solidworks ,etc ) Material Request ( most kinds of plastic and metals are available ) Surface-treatment Request ( painting or nature , glossy or matte , anodized ,etc)QTY needed.

Q3: What is your MOQ ?

A: The Minimum order quantity is : 1 piece.

Q4: Do you provide modifications of drawings or samples ?

A: Yes ,We can make modifications of drawings for clients , also can help to do industrial design ,if customers have products that did not workable , we can also help to repair.

Q5: How long do your factory need for production ?

A: Actually , it is varies depending on the sizes and difficulty of machining ,we still are confident in 4-7days and delivery within 3 days.

Q6: What if your factory made parts with wrong sizes and structures ?

A: In dieser Situation werden wir das Geld an die Kunden zurückgeben. Wenn sich noch eine Chance ergibt, werden wir uns Mühe geben, es zu reparieren oder neu zu gestalten.

Request for Quotation

Request for Quotation